Heavy Machinery Sale of Gantry, Boring and Milling Machines from the Closure of TMG

Starts: 07 October 2025 at 07:00 BST

Ends: 12 November 2025 at 13:00 GMT

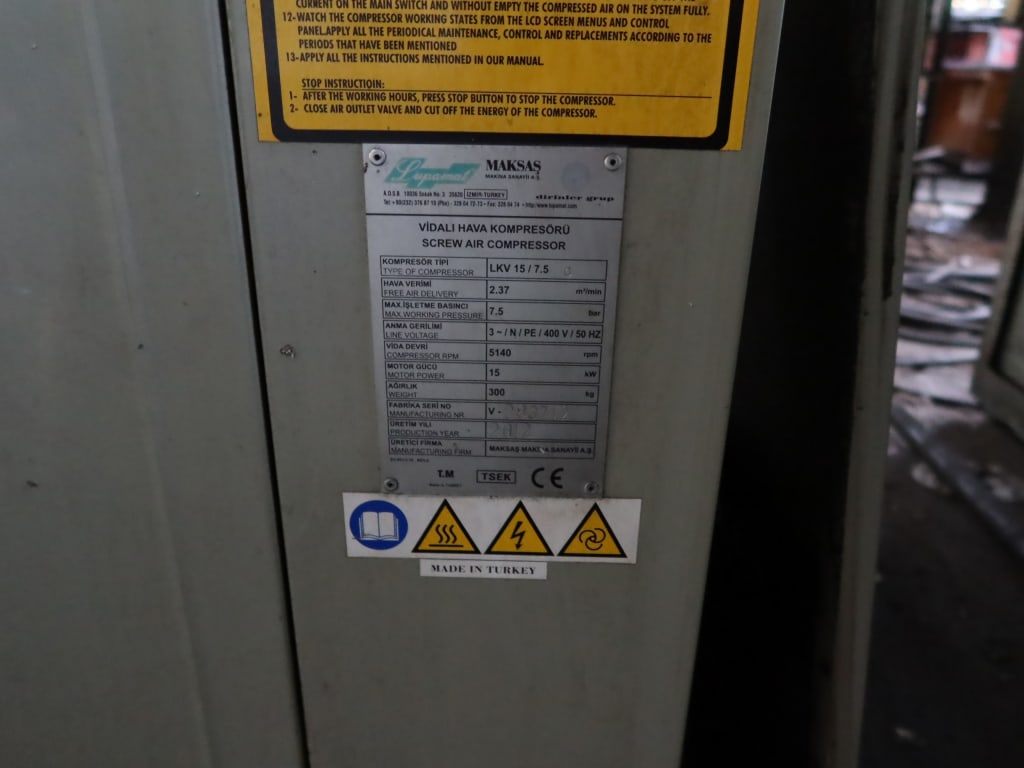

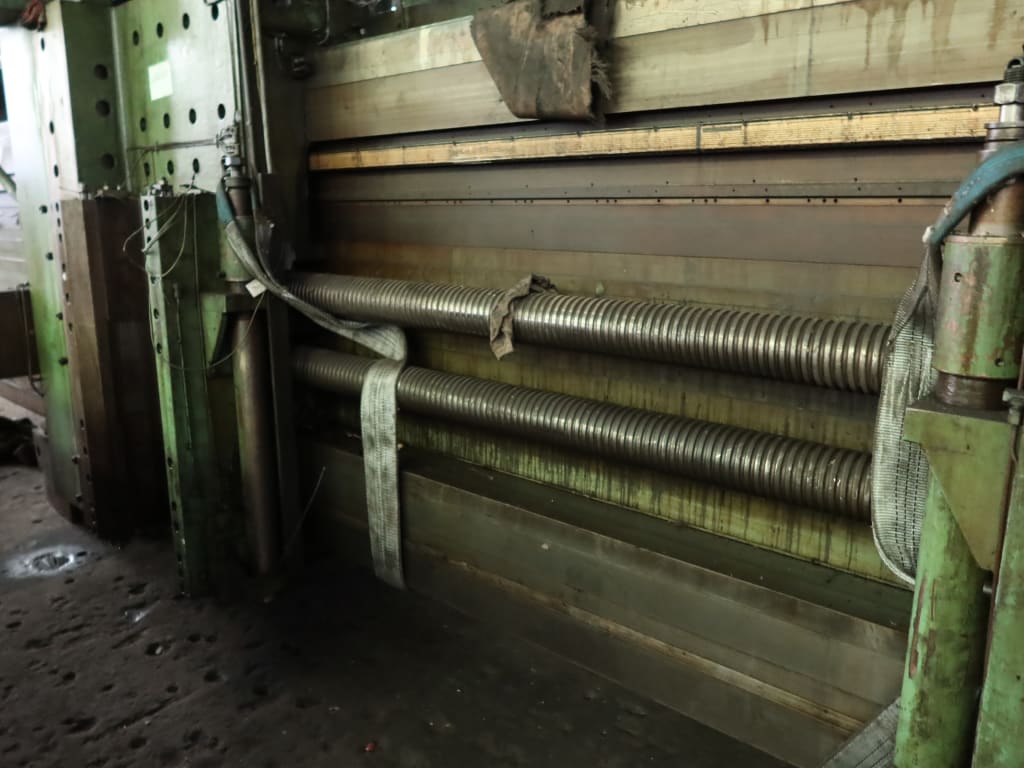

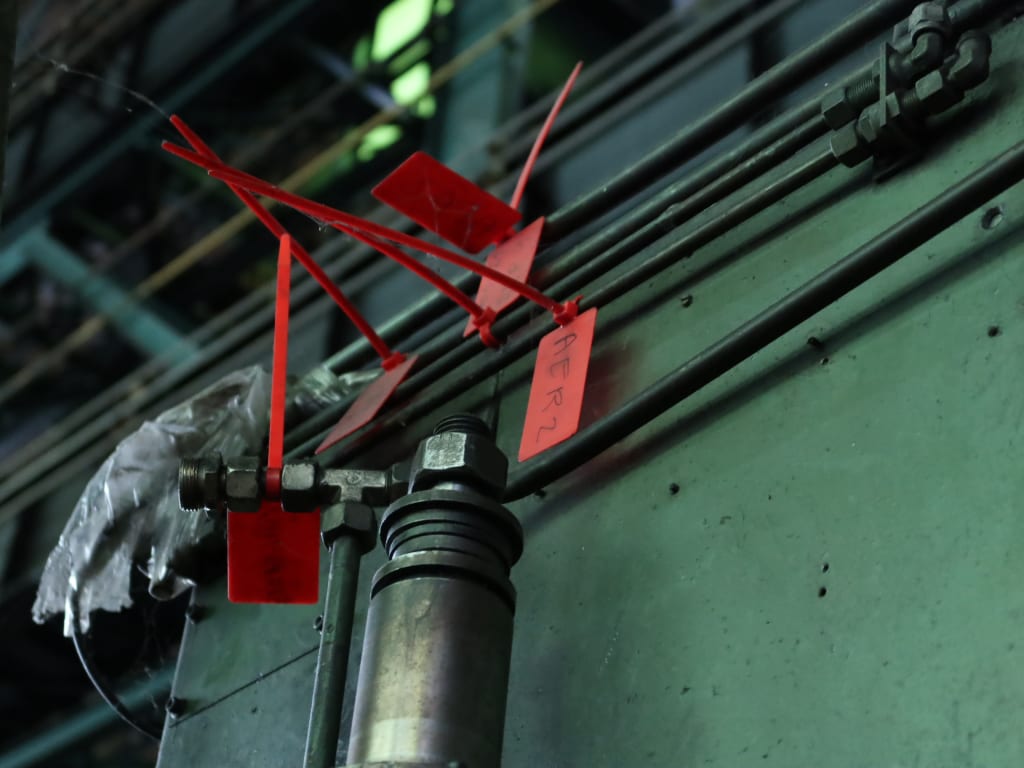

Featuring a Innocenti CWB 150 Boring & Milling machine, Waldrich 30 FS Grinding machine, Waldrich Coburg GM 600-30000 Gantry Milling machine and others due to the closure of TMG. Please note lot 8 is dismantled and stored in 8 stacks as seen in pictures. Please see the sale information section for any additional fees that may be applicable upon purchasing an item. NOTE: Vendor to approve all closing bids prior to Apex final invoicing.

Share:

Showing 9 of 9 lots

- LOT 1

![site]()

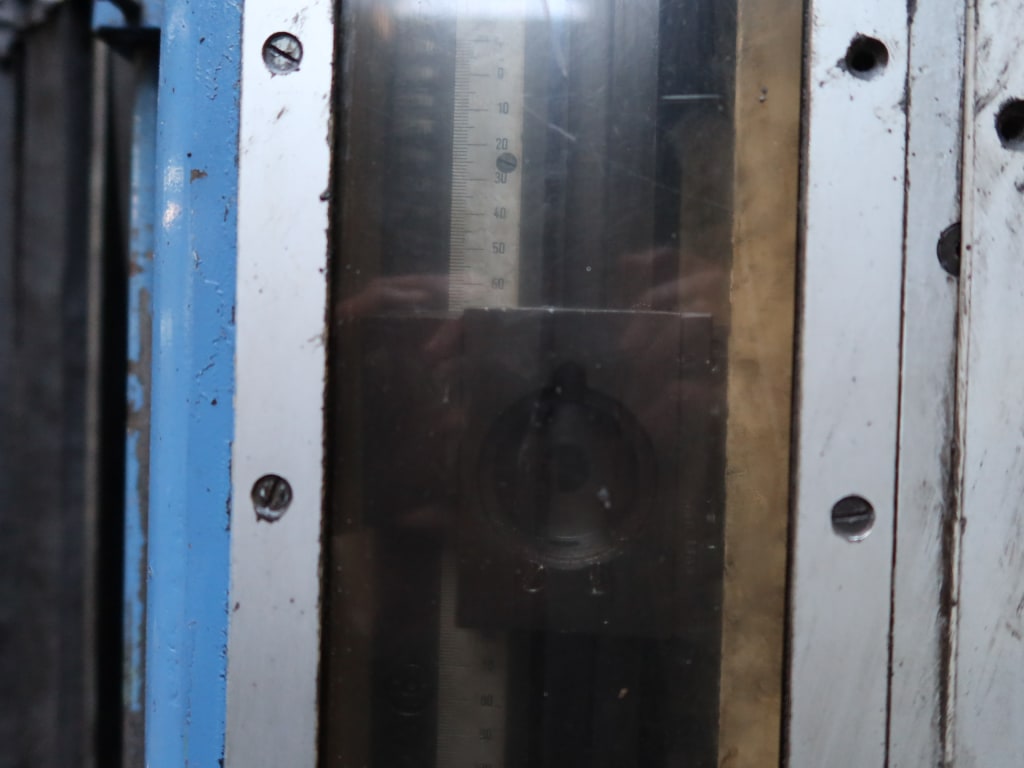

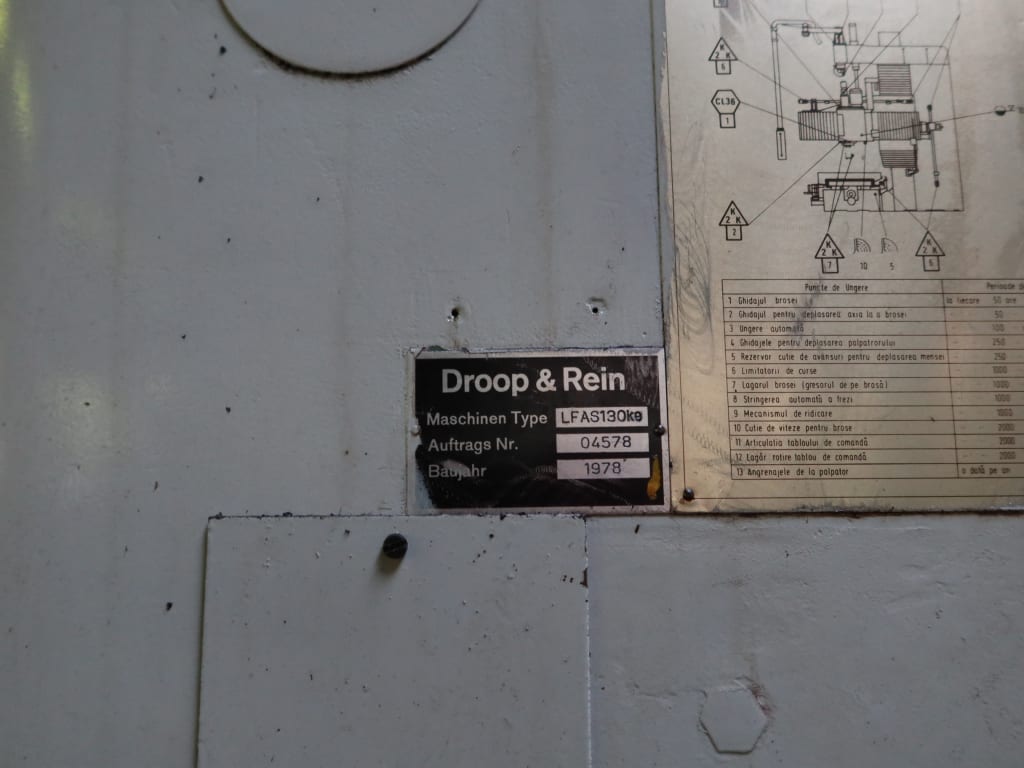

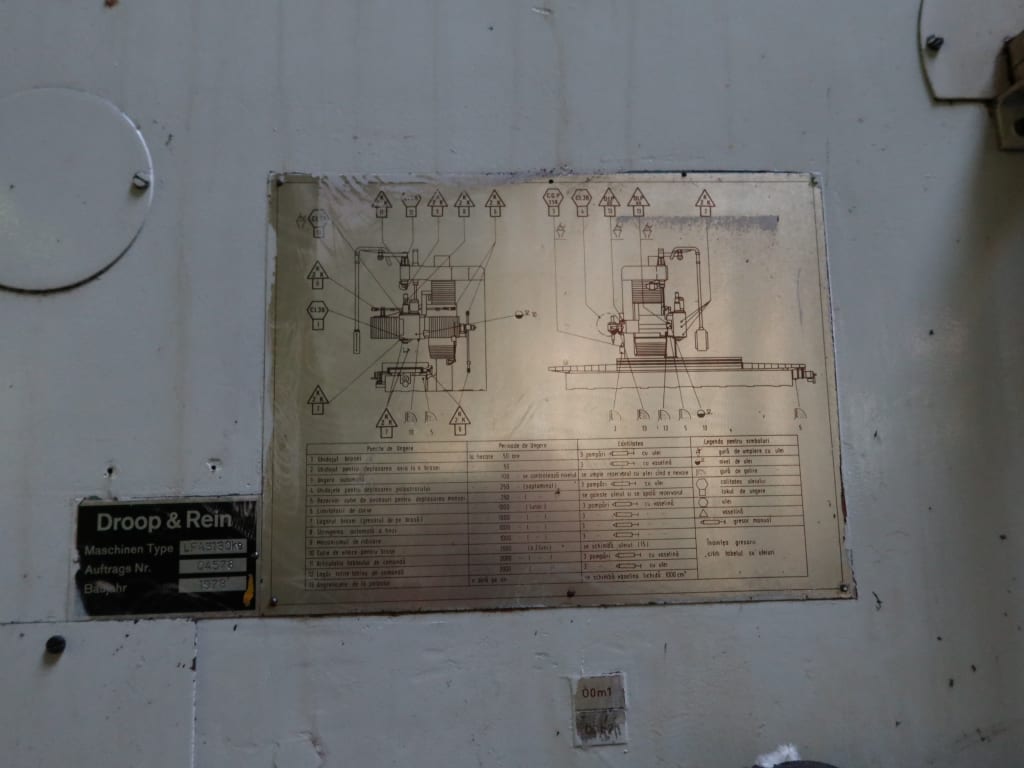

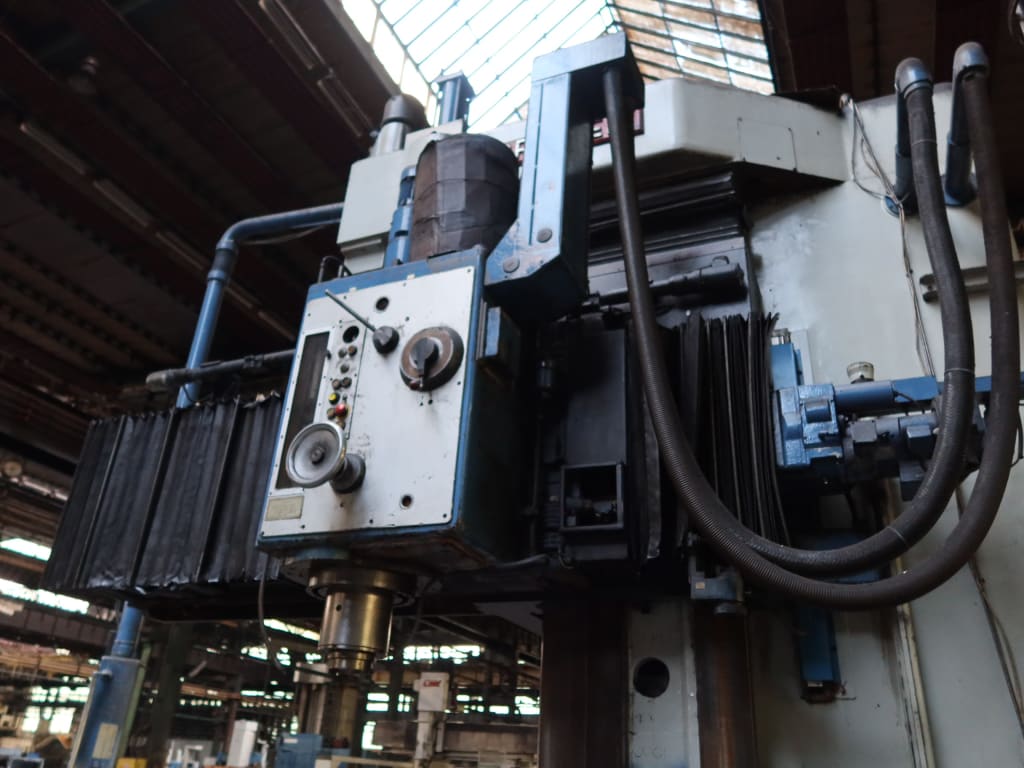

Droop and Rein LFAS130KE Milling Machine (1978)

Axes: X (Table travel) 3,000 mm, Y (Cross-Rail vertical travel) 1,000 mm, Z (Milling Head Saddle on Cross-Rail travel) 1,500 mm, U (Boring Bar vertical travel) 300 mm. Axes Feeds: X min 20 mm/min, max 2,000 mm/min; Y min 20 mm/min, max 2,000 mm/min; Z min 20 mm/min, max 2,000 mm/min; U manually. Note: The X, Y, Z axes are equipped with linear encoders. On the control panel there is a display unit (DRO) for the X, Y, Z axes. For the U axis, direct viewing on a graduated ruler is used. Moving Table Load: max. 20,000 kg/m (uniform distribution on table surface). Moving Table usable surface: 4,000 × 1,600 mm. Moving Table total surface: 4,900 × 1,600 mm. Distance between Table and Cross-Rail: max. 1,200 mm. - LOT 2

![site]()

Forest CNF 160 CNC Boring and Milling machine (1974, retrofitted in 2004)

Machine – CNC Axes: X (Column Saddle travel) 12,500 mm, Y (Headstock Saddle Vertical travel) 3,500 mm, Z (Boring Shaft travel) 1,250 mm, W (Quill travel) 1,000 mm, W+Z (Cumulative travel) 2,250 mm. Rotary Table – CNC Axes: W2 (Table travel) 3,200 mm, B (Table rotation) 0–360°. Rotary Table Surface: 2,500 x 3,500 mm. Rapid Feed Axes: X max. 5,000 mm/min, Y max. 5,000 mm/min, Z max. 3,000 mm/min, W max. 3,000 mm/min, W2 max. 2,000 mm/min, B max. 1 rot/min. Work Feed Axes: X 1–2,000 mm/min, Y 1–2,000 mm/min, Z 1–1,000 mm/min, W 1–1,000 mm/min, W2 1–200 mm/min, B 0.1–1 rot/min. Milling Spindle Range (S – Gearbox with 4 mechanical ranges): Range #1 2.5–80 rpm, Range #2 80–160 rpm, Range #3 160–320 rpm, Range #2: 320 - 630 rpm. Boring shaft taper bore: ISO 50, Boring shaft diameter: 160 mm. FANUC 18M Contouring Numeric Control. FANUC made feed axes motors. FANUC made spindle motor. FANUC made drive system for axes and spindle motors. - LOT 3

![site]()

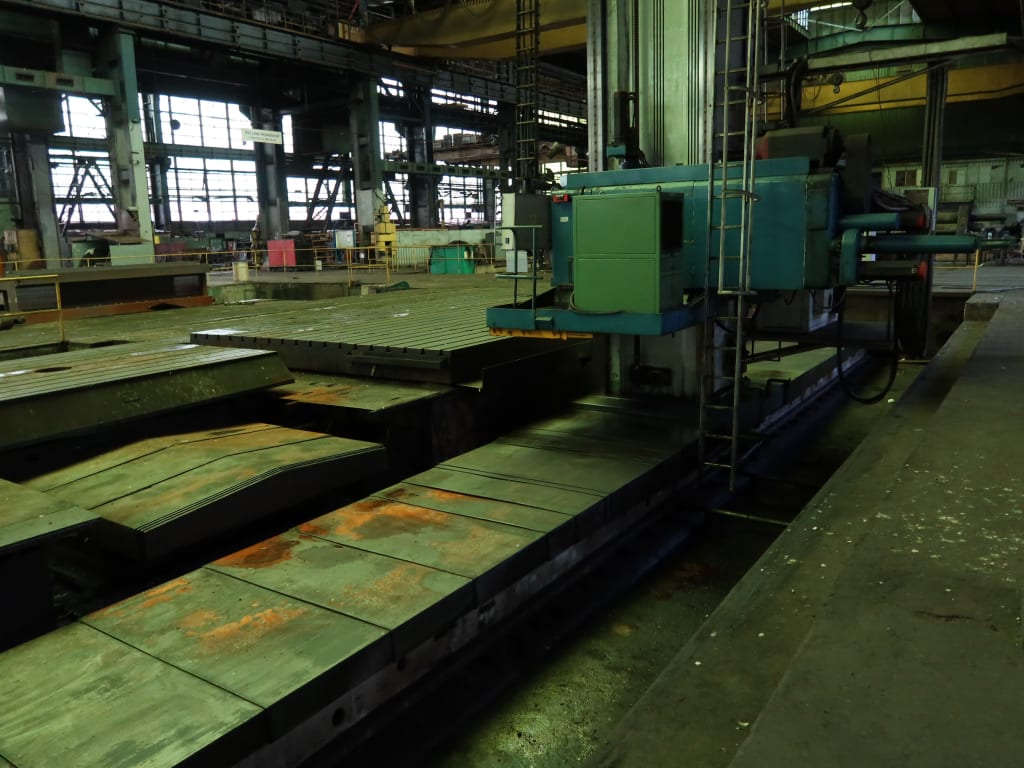

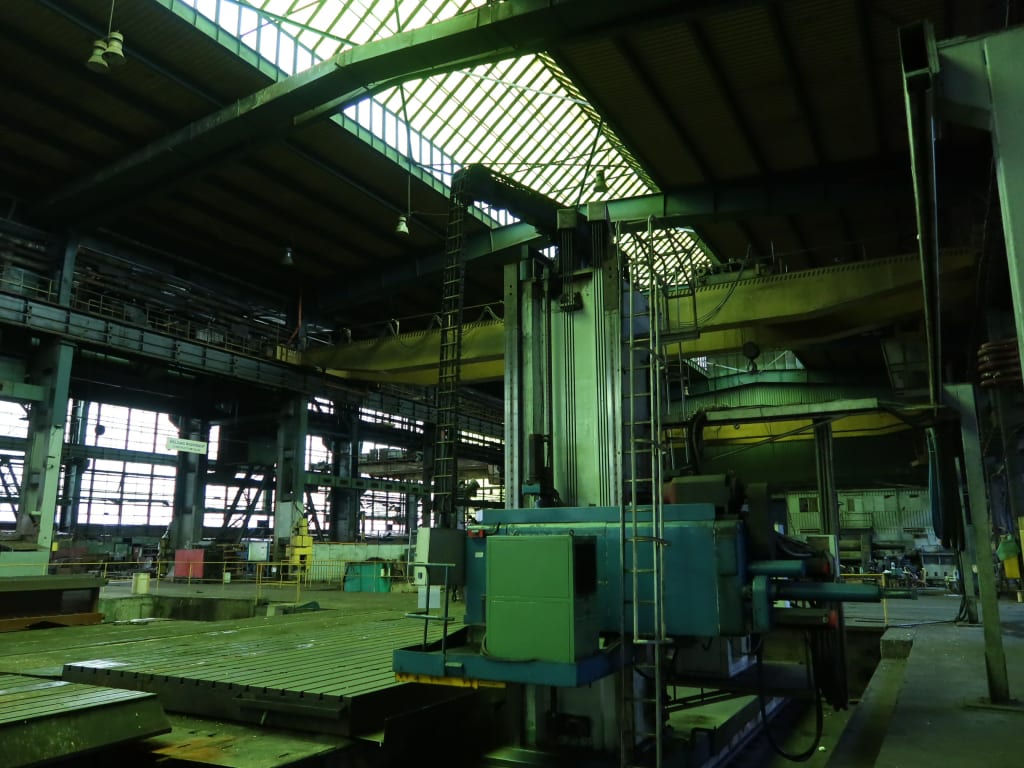

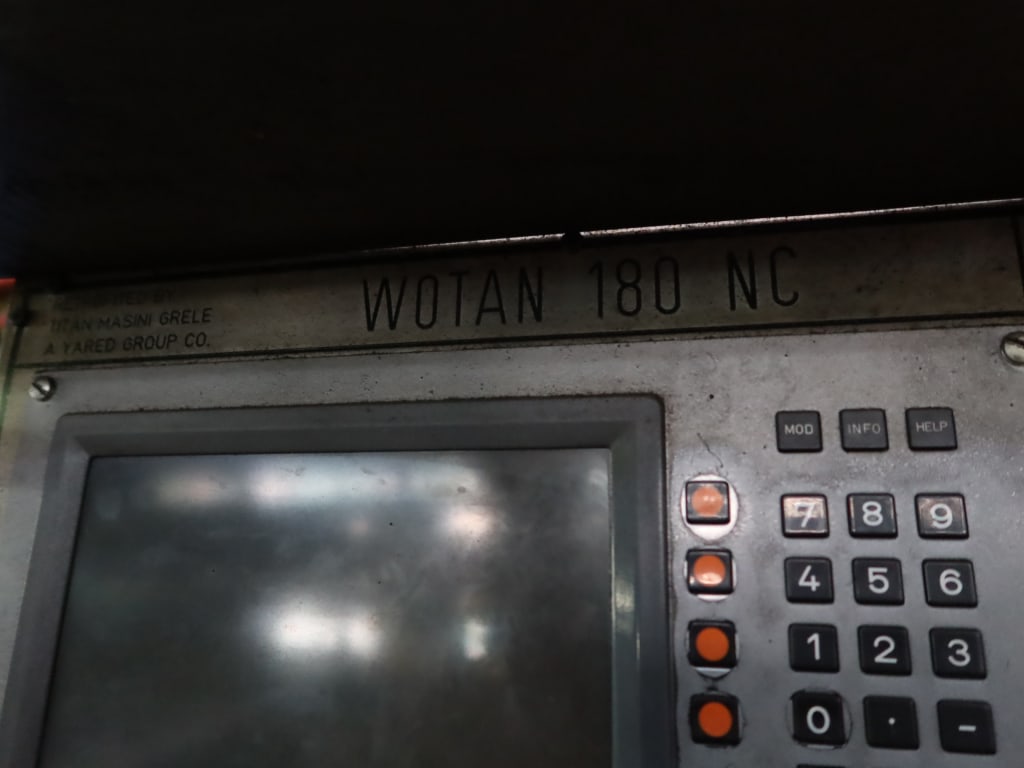

Wotan HBM 180 CNC0TNC 124 Boring and Milling Machine (1981, retrofitted in 1999)

NC Positioning Axes: X (Column Saddle travel) 9,720 mm, Y (Headstock Saddle vertical travel) 2,739 mm, Z (Boring and Milling Shaft travel) 1,240 mm. NC Only Display Axis: B (Rotary Table travel) 0–360 degrees with 4 positions at 90 degrees. DRO Axis: W (Perpendicular Column Saddle travel) 700 mm. Feed Range: X 1–1,600 mm/min, Y 1–1,600 mm/min, Z 1–1,600 mm/min, W 1–1,000 mm/min. Rapid Axes Feed: X max. 2,000 mm/min, Y max. 2,000 mm/min, Z max. 2,000 mm/min, W max. 1,000 mm/min. Milling Spindle Range (Constant Torque / Constant Power): Range 1: 37–72 rpm, Range 2: 73–143 rpm, Range 3: 205–406 rpm, Range 4: 405–800 rpm. Rotary Table Surface: 2,500 × 3,000 mm. Rotary Table Load: max. 20,000 kg (center weight of piece in center of table). Fixed Table Surface: 6,000 × 3,000 mm. Overall Size Dimension (without Device Cabinet): H x W × L = 7,800 × 10,500 × 16,000 mm. Machine Weight (with Tables): approximately 72,000 kg. Machine was retrofitted in 1999 by TMG SA. TNC 124 Positioning Numeric Control HEIDENHAIN, controlling axes X, Y, Z and only display axis B. 4 × 1FT5 SIEMENS feed axes motors (X, Y, Z, W). 1 PH7 SIEMENS 37kW spindle motor (S) with SIEMENS SIMODRIVE 611A for axes and spindle motors. Boring capability included. - LOT 4

![site]()

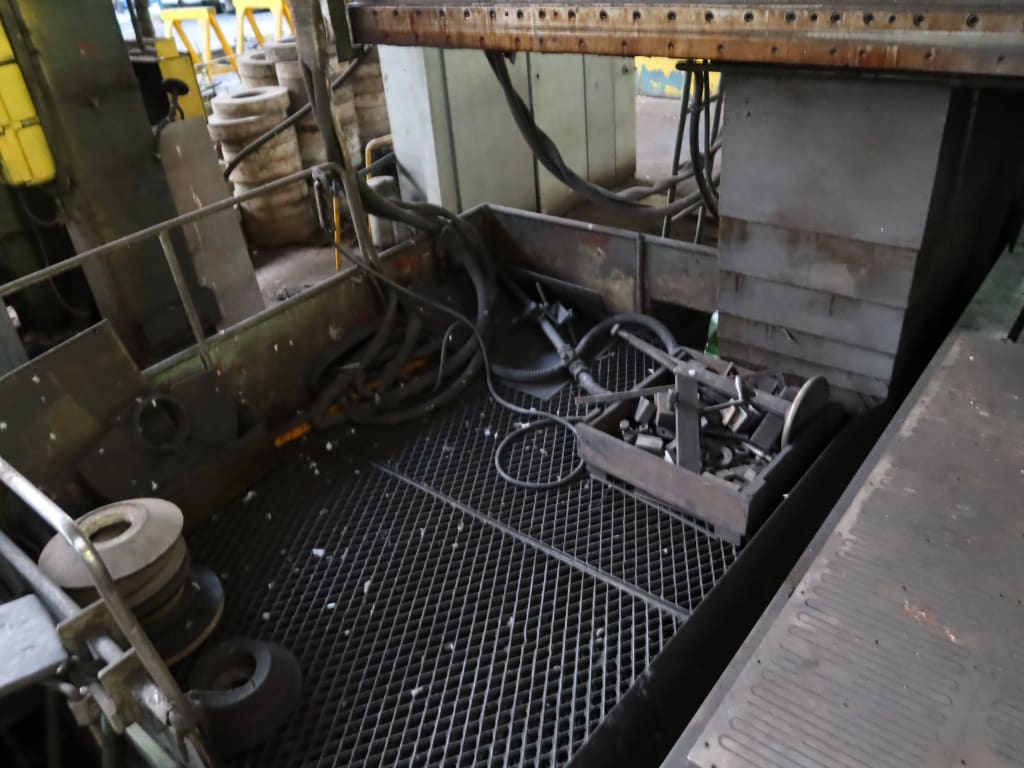

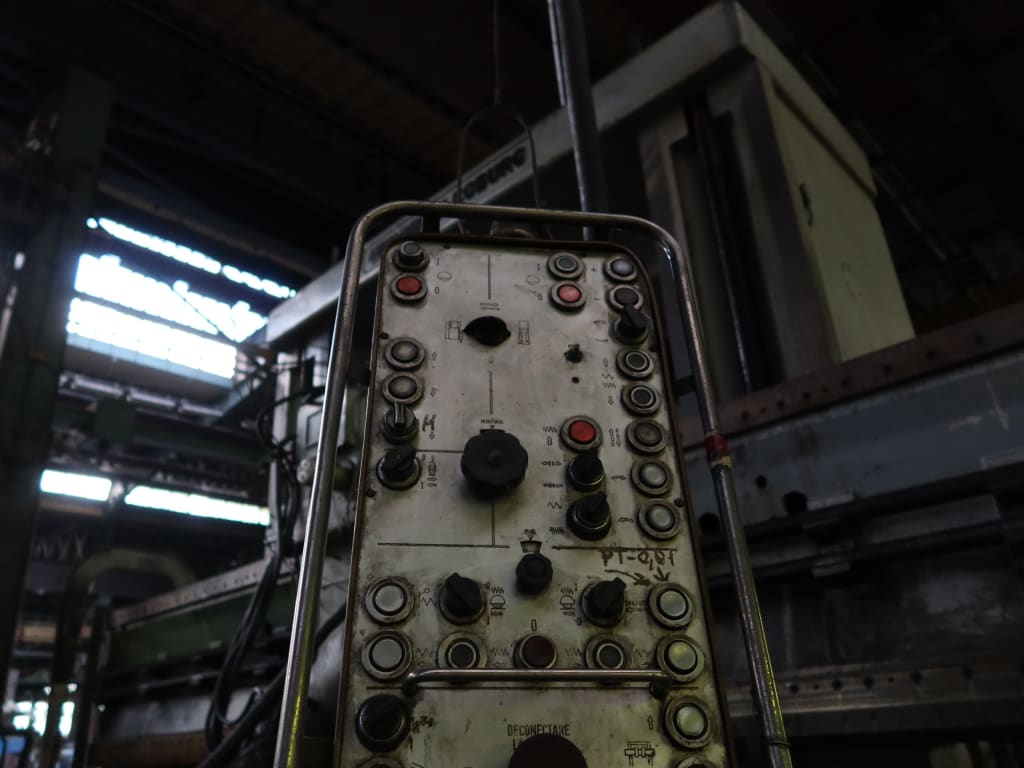

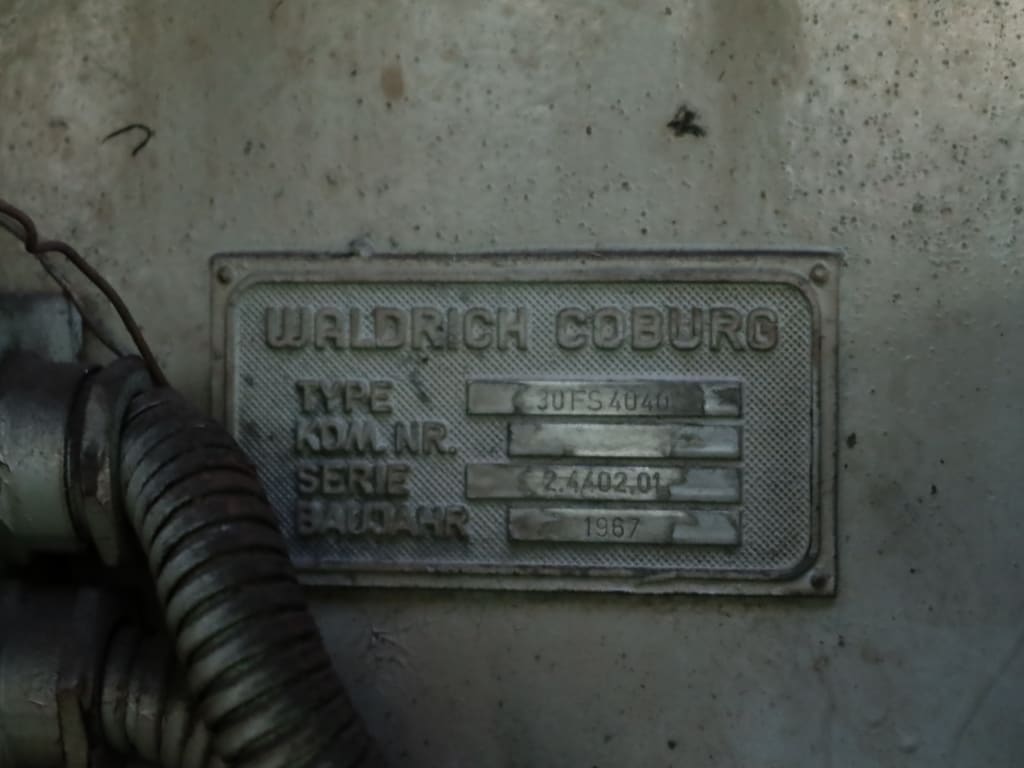

Waldrich Coburg 30 FS 4040 Slide Grinding Machine (1967)

Mobile Table Dimension 2,000 x 9,000mm. Traverse Stroke 2,000mm (Cross Travel). Distance Between Columns 2,200 mm. One Reclining Head. Travel head on the Crossrail = approx. 3,500mm (Horizontal Travel). Wheel Dimensions: From 180 mm to 500 mm. Coolant system: Yes. Filtration System: Yes. Wheel speed range: from 1100 to 3200 rpm (maximum 25 m/s). - LOT 5

![site]()

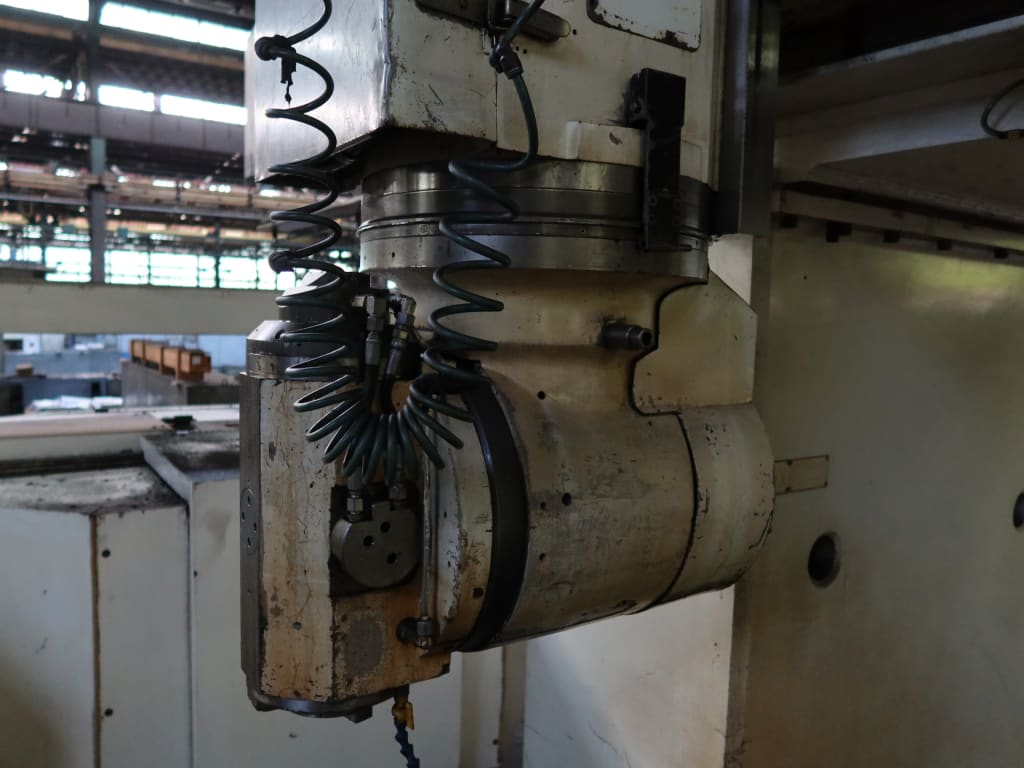

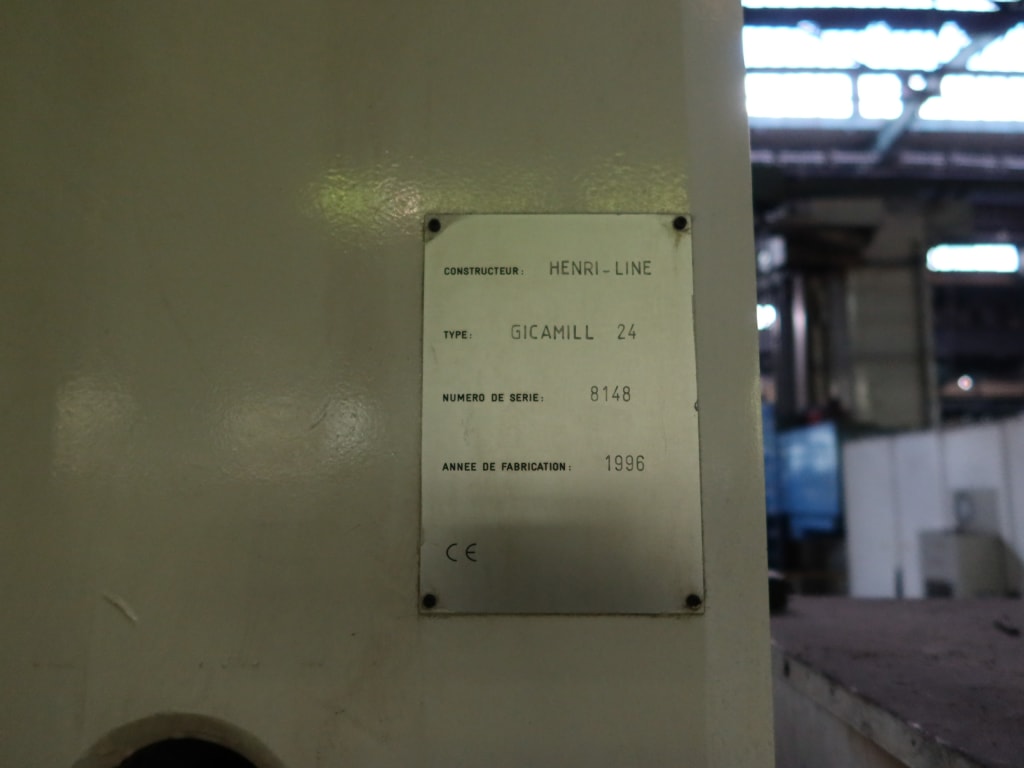

Henri Line GICAMILL 24 CNC Gantry Milling Machine Line (1996)

Main CNC Axes: X1+X2 (Gantry axes Portal travel) 6,000 mm, Y (Milling Head horizontal travel on Cross-Rail) 3,500 mm, Z (Milling Head vertical RAM travel) 1,000 mm; CNC Accessory Axes (Universal Head): A (Rotation around the X axis) angular movement -120 to 0 to +120 degrees with 1 degree step, lock with HIRTH; C (Rotation around the Z axis) angular movement 0–360 degrees with 1 degree step, lock with HIRTH; Feed Range: X 1–10,000 mm/min, Y 1–10,000 mm/min, Z 1–10,000 mm/min; Rapid Axes Feed: X max. 15,000 mm/min, Y max. 15,000 mm/min, Z max. 10,000 mm/min; Milling Spindle Speed Ranges: Range 1: 20–207 rpm Constant Torque / 208–897 rpm Constant Power; Range 2: 50–925 rpm Constant Torque / 926–4,000rpm Constant Power; Motor Milling Spindle (S1): SIEMENS 1PH6167-4NF49-Z, nominal speed 1,500 rpm, max. speed 6,500 rpm, 37 kW, 102 A, with SIMODRIVE 611A; Active Table Surface: 6,100 × 2,200 mm; Distance between Columns: 2,550 mm; Distance between Table and Cross-Rail: 1,650 mm; Milling Tool-Holder: type ISO 50Accessories include Angular Universal Head (angular axes A and C) and Direct Drive Milling Head with Milling unit HFWS 1718, ISO 40, motor 12 kW, 26 A, 18,000 rpm at 600 Hz, drive SIEMENS SIMODRIVE 611A. (1996) - LOT 6

![site]()

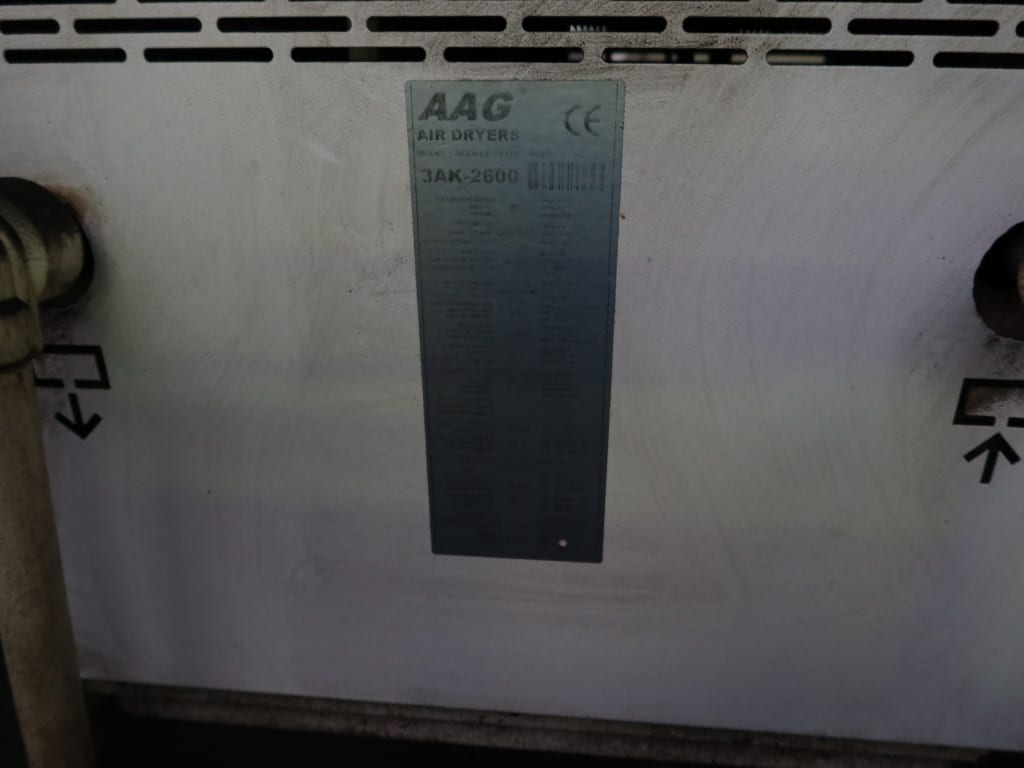

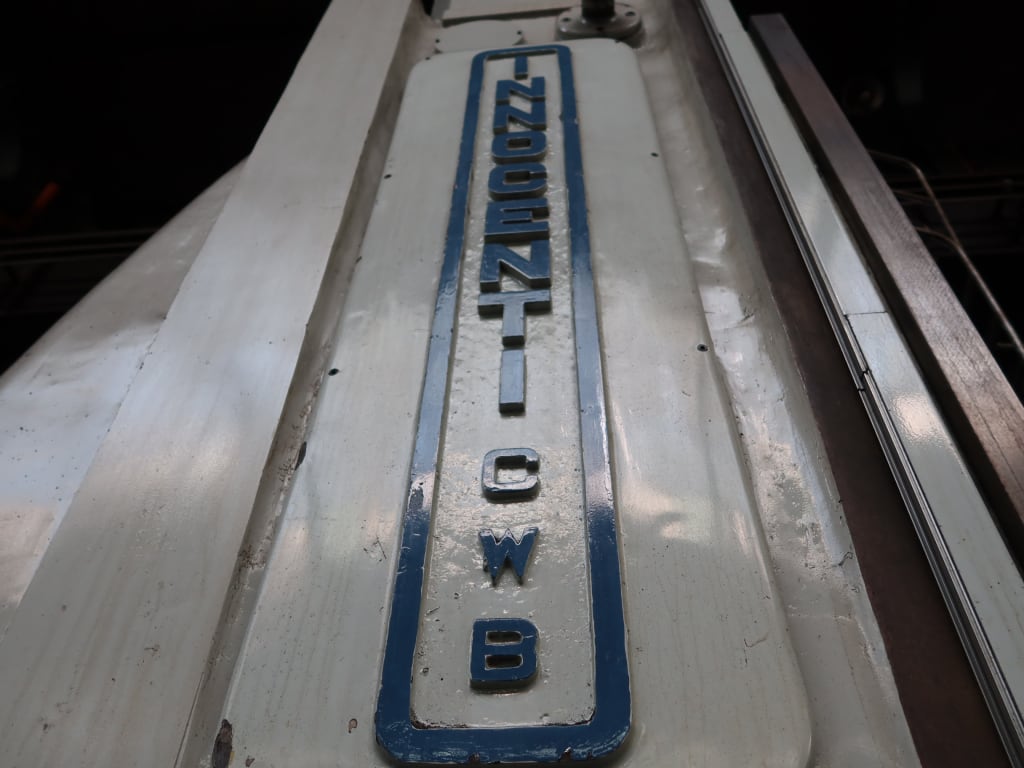

Innocenti CEB 150 Floor Type Horizontal Boring and Milling Machine (1962, Retrofitted In 2000)

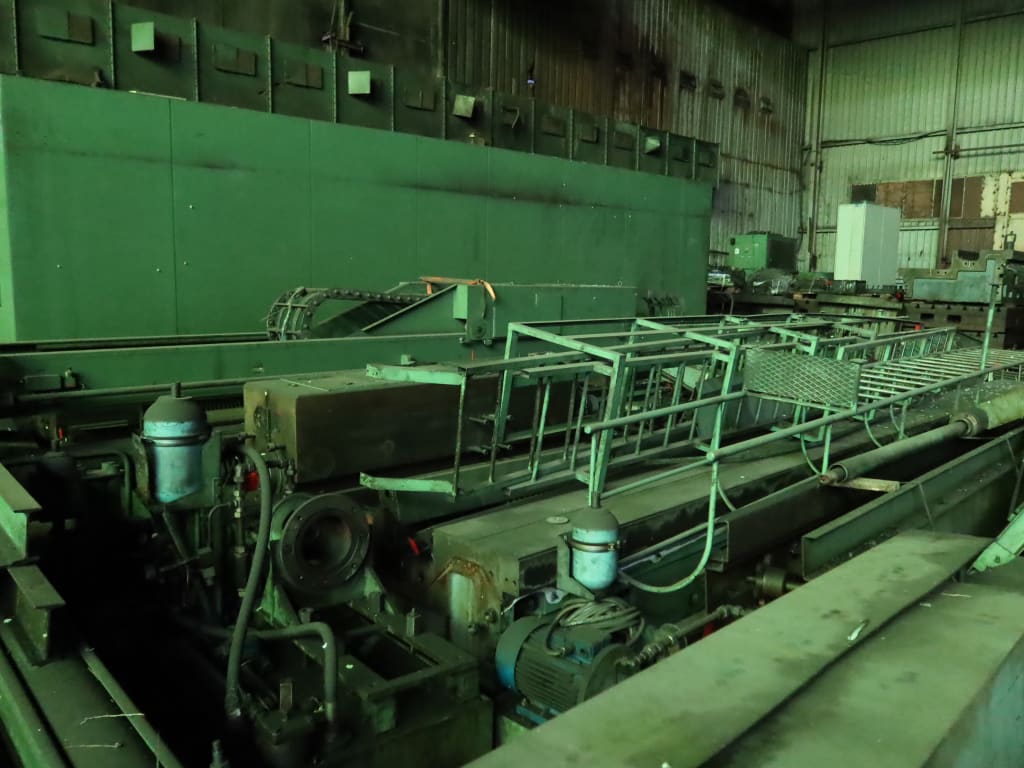

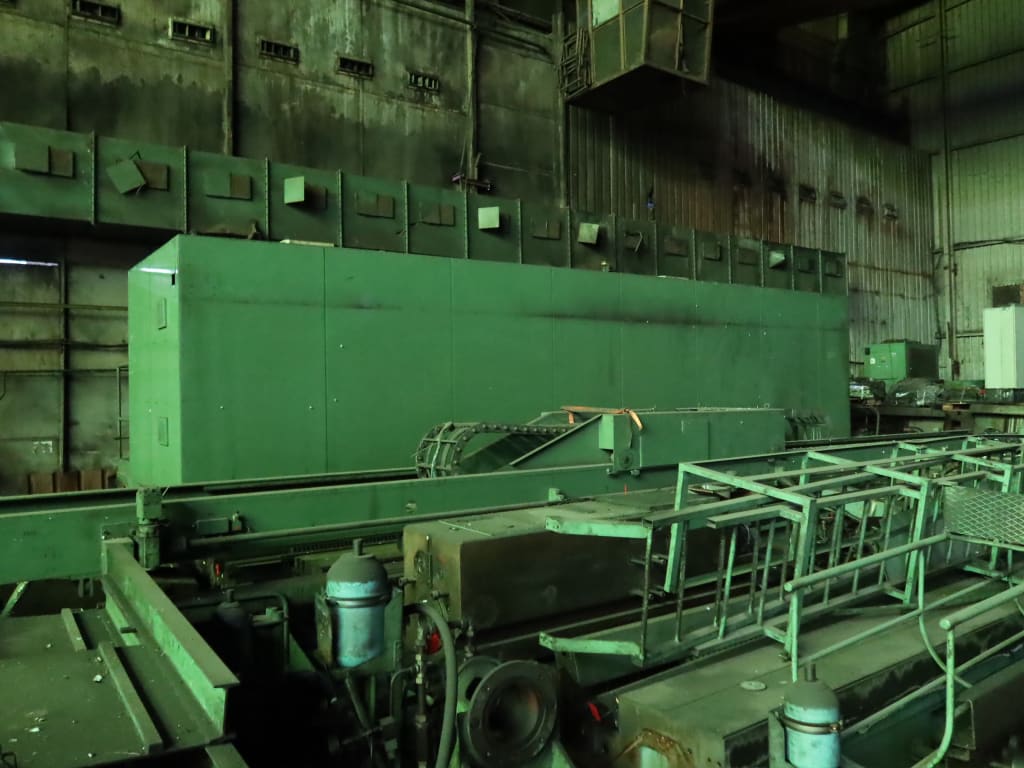

Table Dimensions 1.450 x 6.000 mm; Number of Axis: 3; Axis Travel X = 4.500 mm Y = 2.500 mm Z = 1.200 mm; Overall Dimensions: L 13.500 x W 7.000 x H 6.500 mm - LOT 8

![site]()

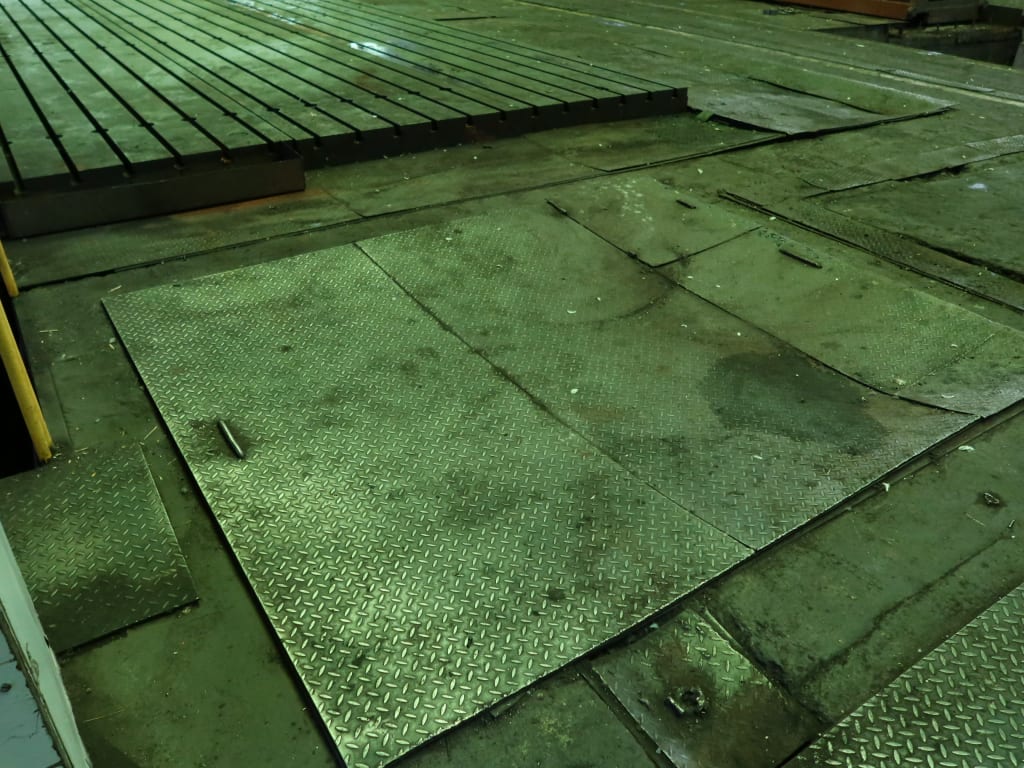

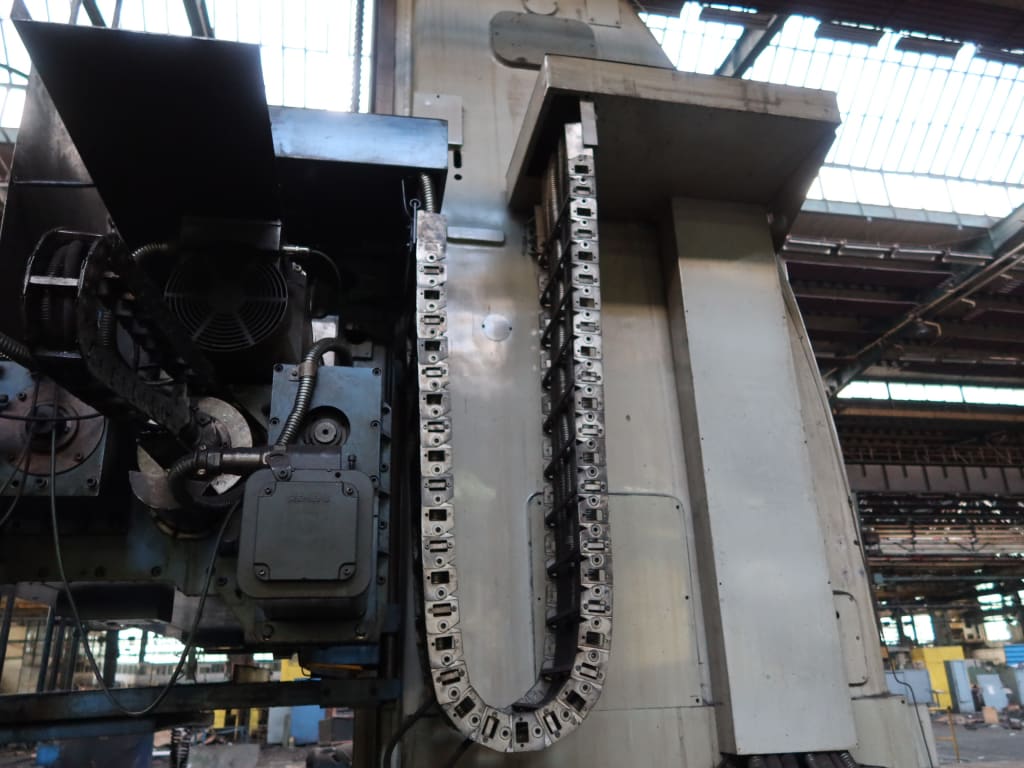

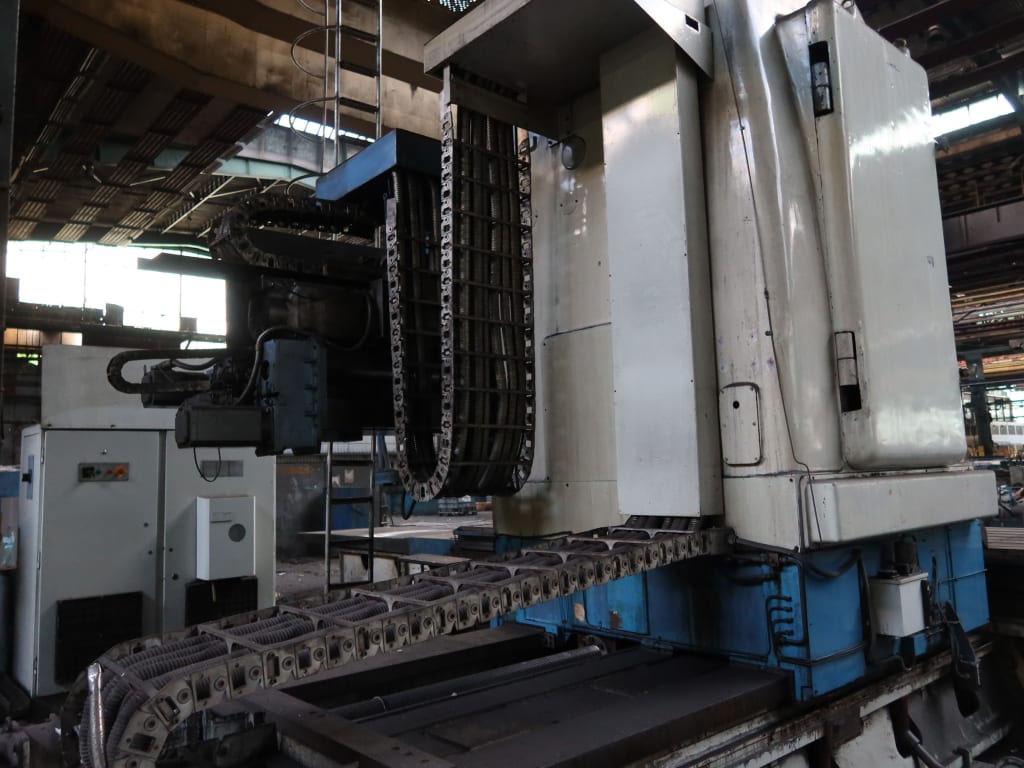

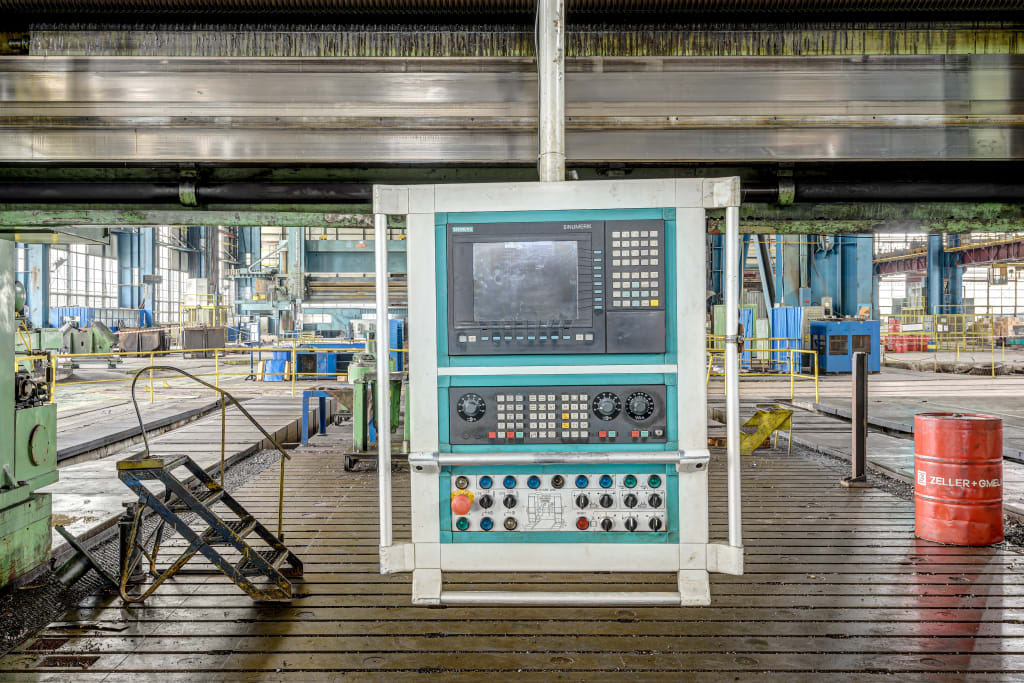

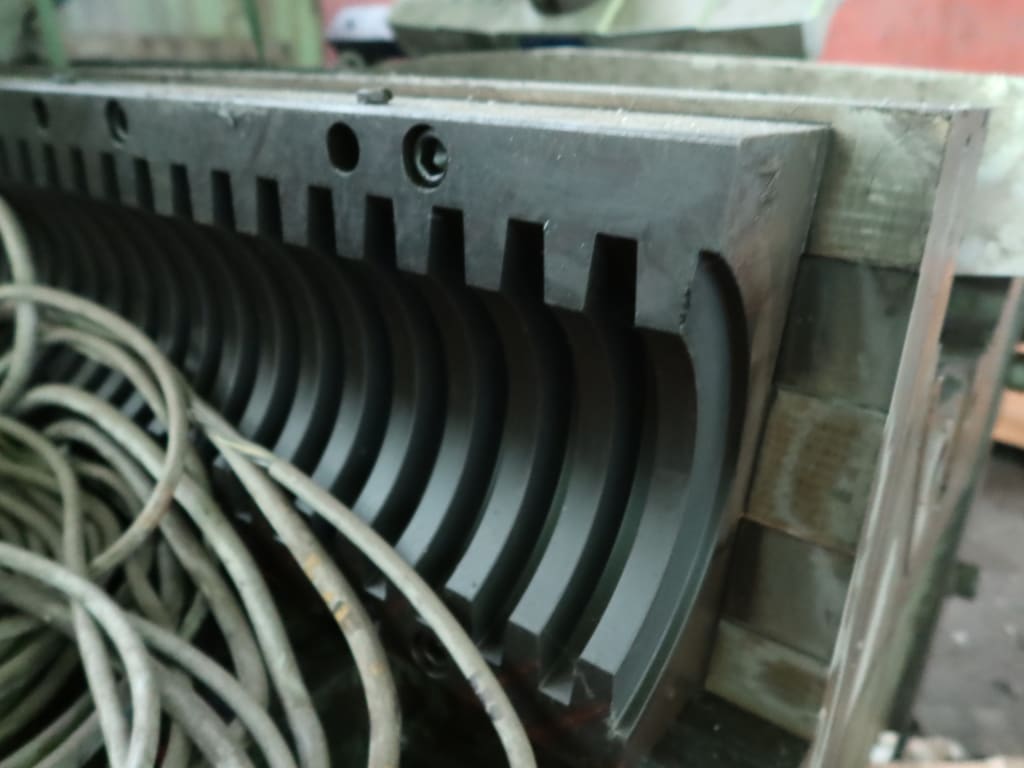

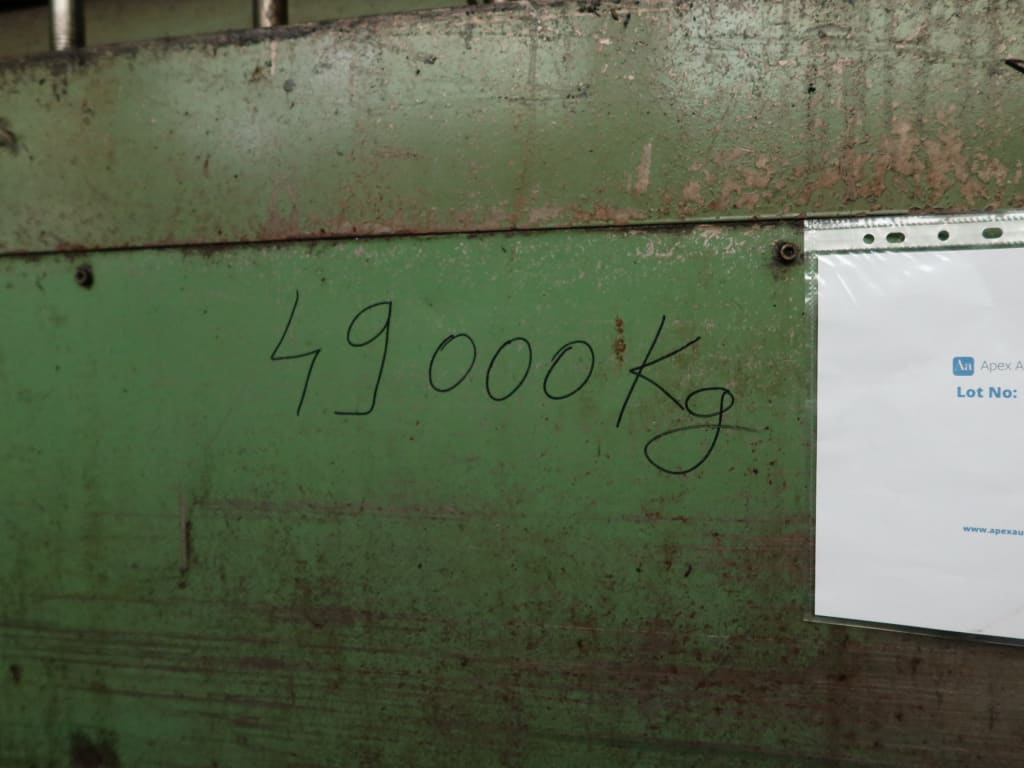

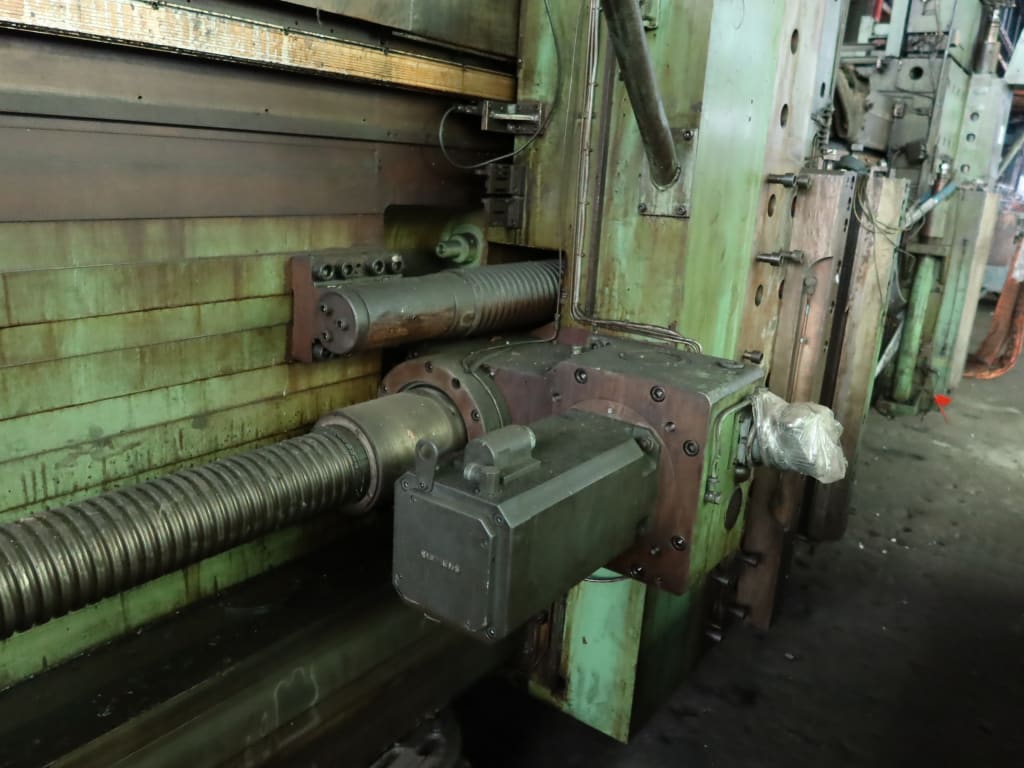

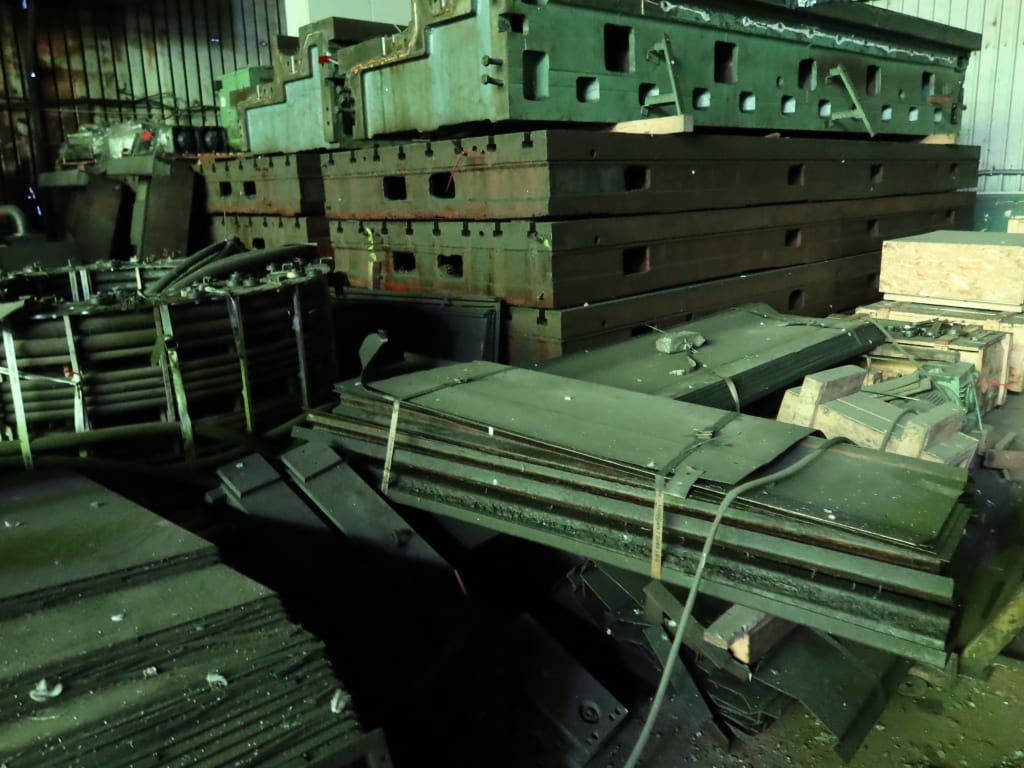

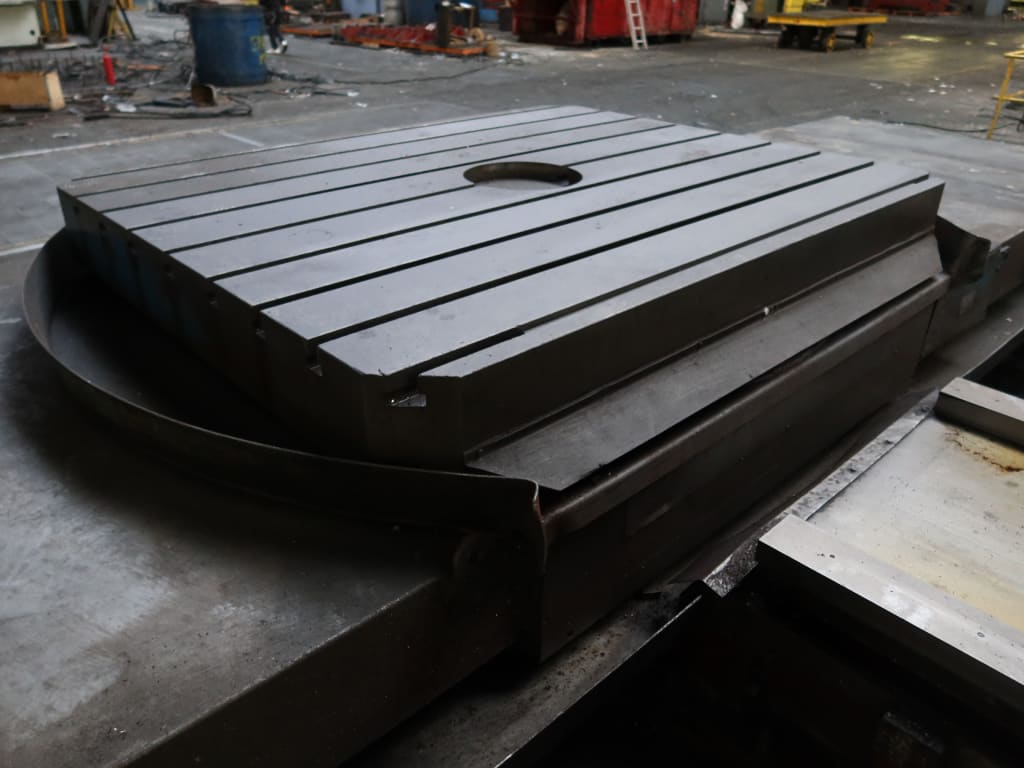

Waldrich Coburg GM 600/30000 CNC Gantry Milling Machine (1979, retrofitted in 2004)

Operation System SIEMENS 840; Technical Specifications: Fixed table length 36,000 mm, Fixed table width 6,000 mm; Distance between columns with covers 6,900 mm, without covers 7,100 mm; Gantry travel 30,000 mm; Cross rail travel 3,100 mm; Milling heads (right and left) travel on cross rail 7,400 mm; Vertical travel of right and left rams 1,000 mm; Gantry work feeds 0–6,000 mm/min; Gantry rapid feed 10,000 mm/min; Milling heads (right and left) work feeds 0–3,000 mm/min; Milling heads (right and left) rapid feed 3,000 mm/min; Vertical rams (right and left) work feeds 0–2,000 mm/min; Vertical rams (right and left) rapid feed 2,000 mm/min; Cross rail fine positioning 0–750 mm/min; Cross rail rapid feed 1,000 mm/min; Fine positioning for work axes 5 mm/min; Main spindles (right and left) speed range on 3 steps 4–475 rpm; Taper of milling spindles ISO 60; Manual 12-head changing system with 8 sets of milling heads; Diameter of milling-spindle nose 221.44 mm; Fixed Table PMM GM600-30000 4,500 × 30,000 mm. - LOT 9

![site]()

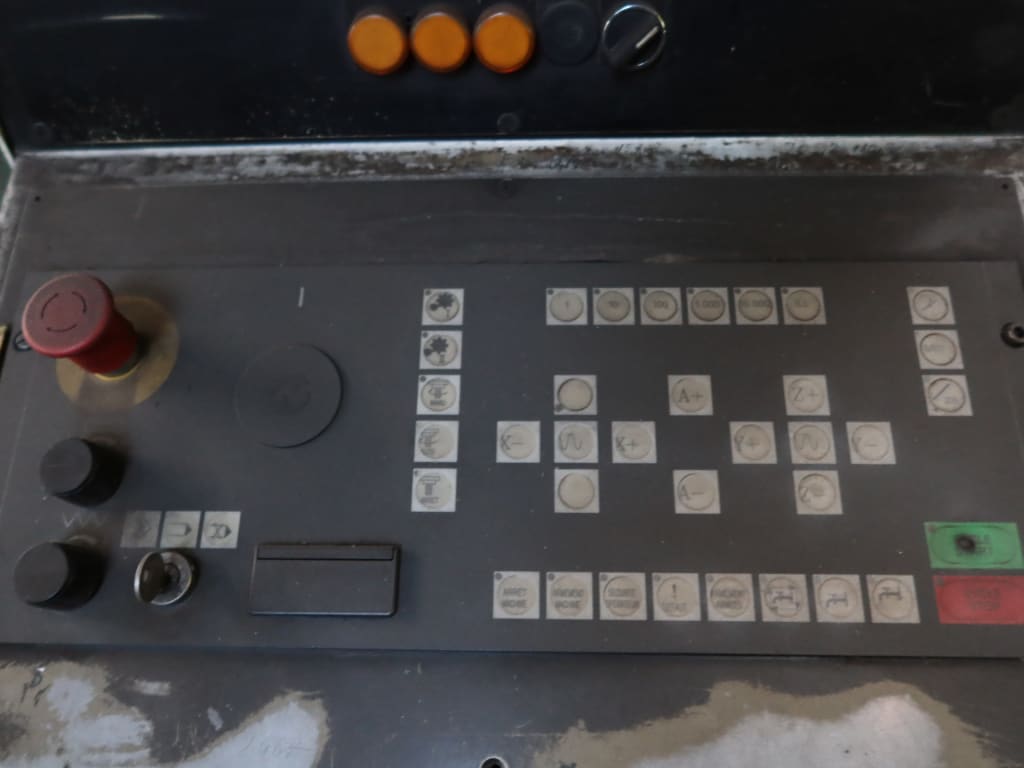

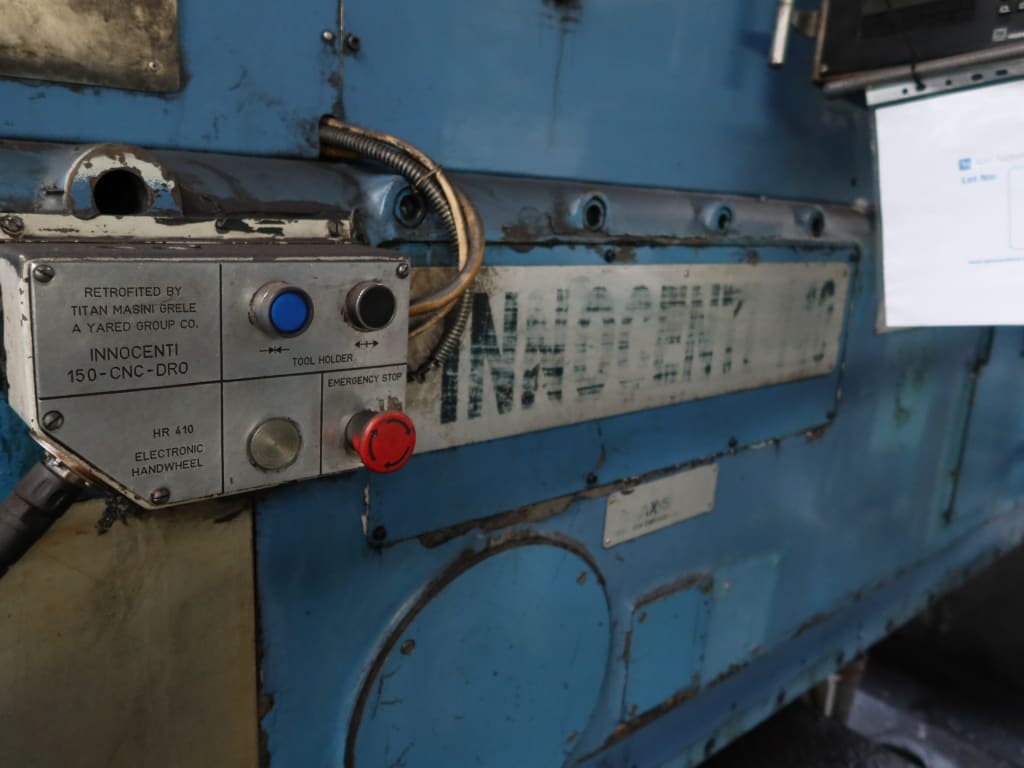

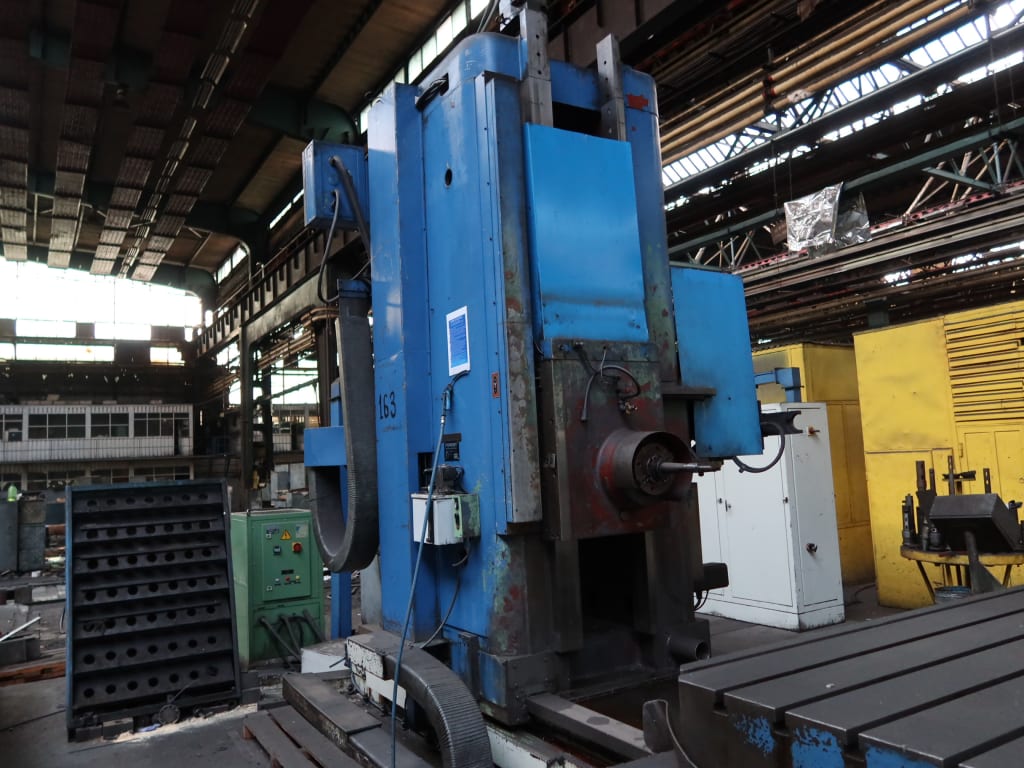

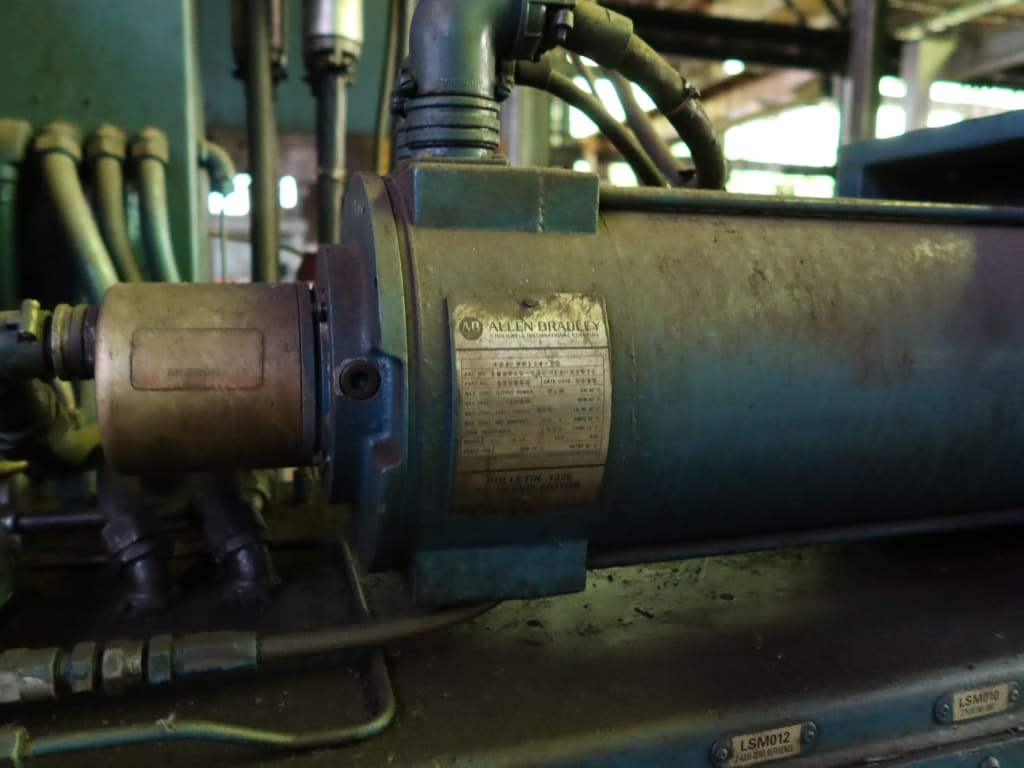

Forest CU10ALM CNC Boring and Milling Machine (1978, retrofitted With Siemens Control)

Table dimensions W x L: 1600 X 2000 mm; Strokes: X = 3500 mm, Y = 2000 mm - LOT 10

![site]()

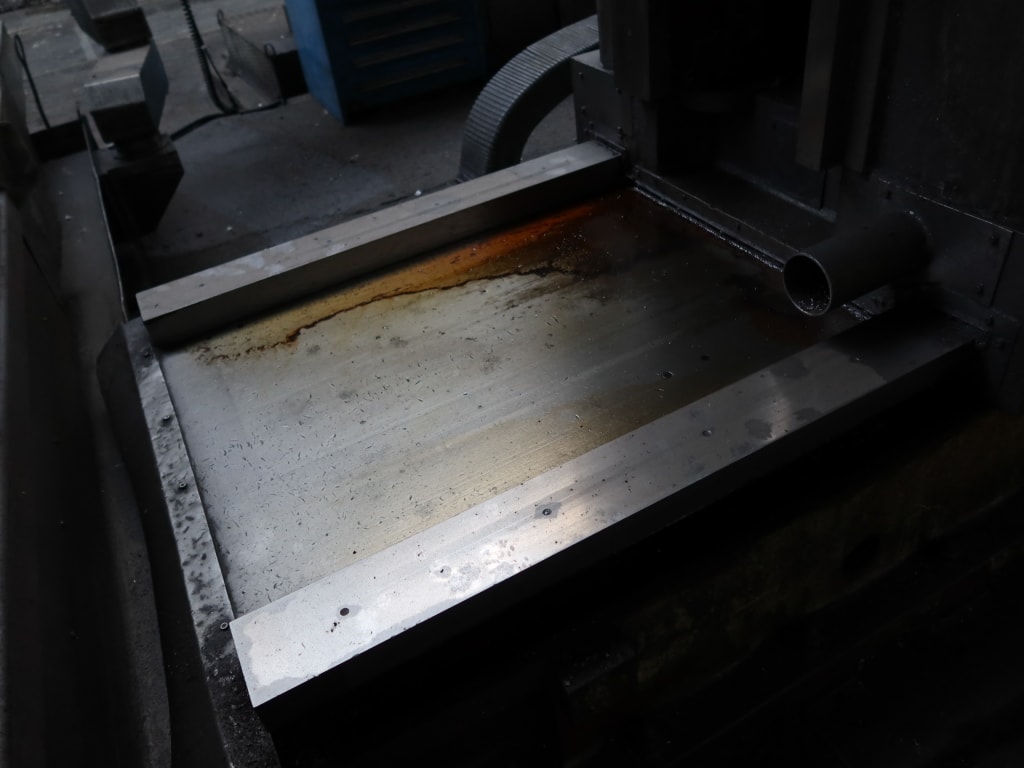

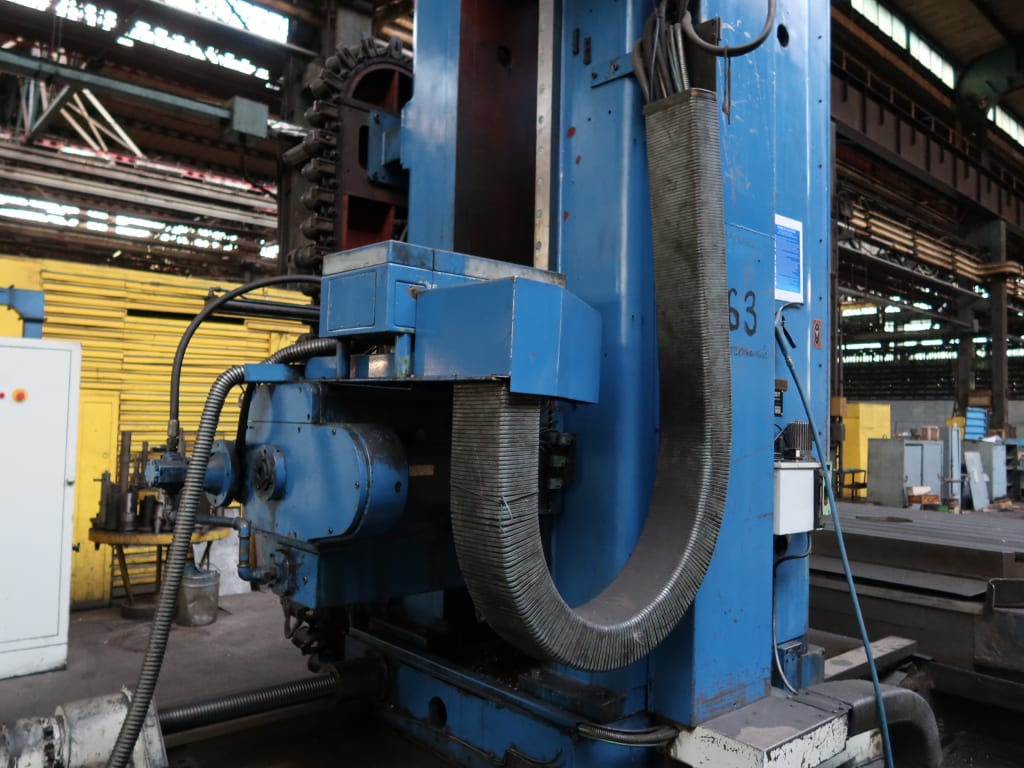

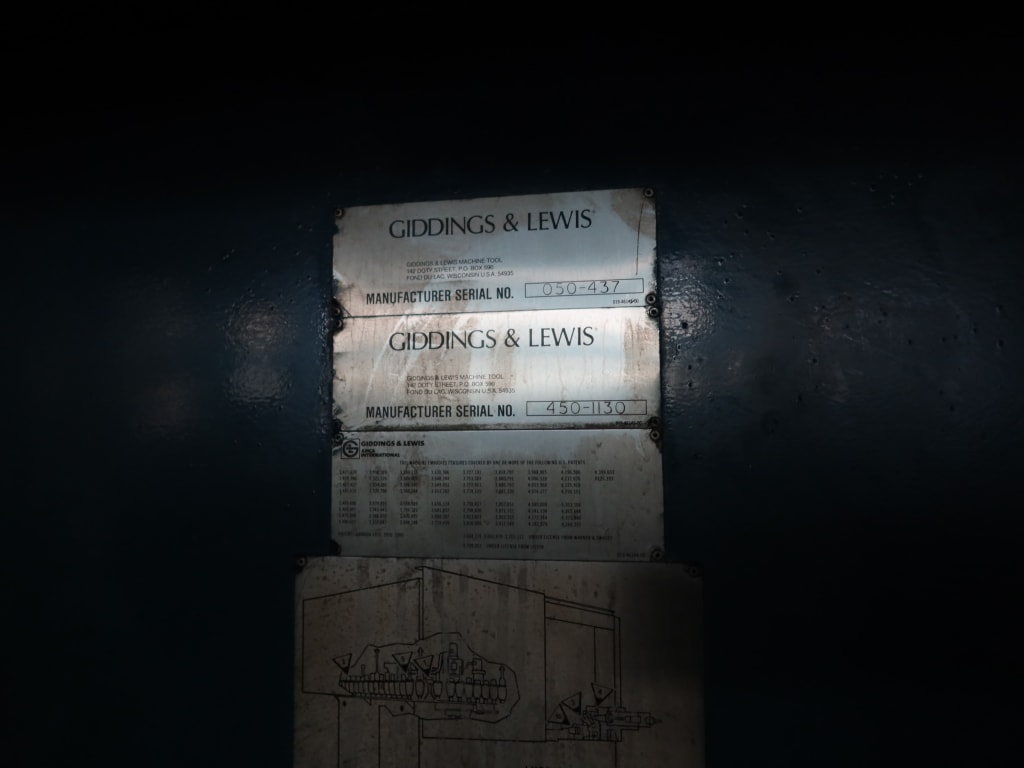

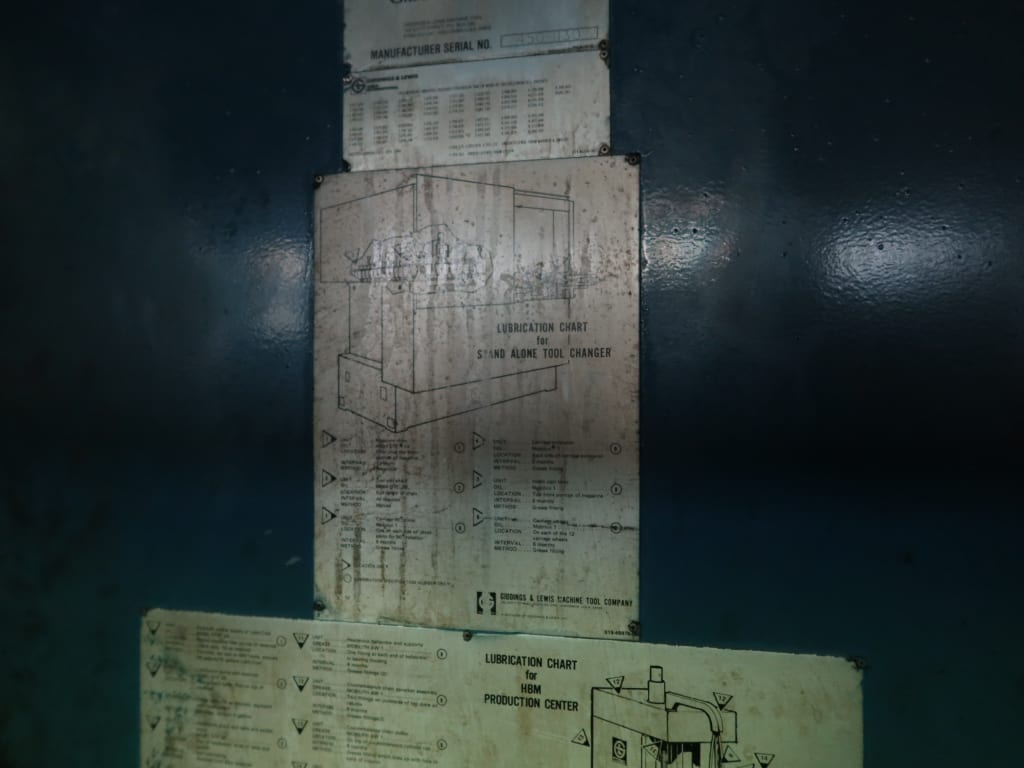

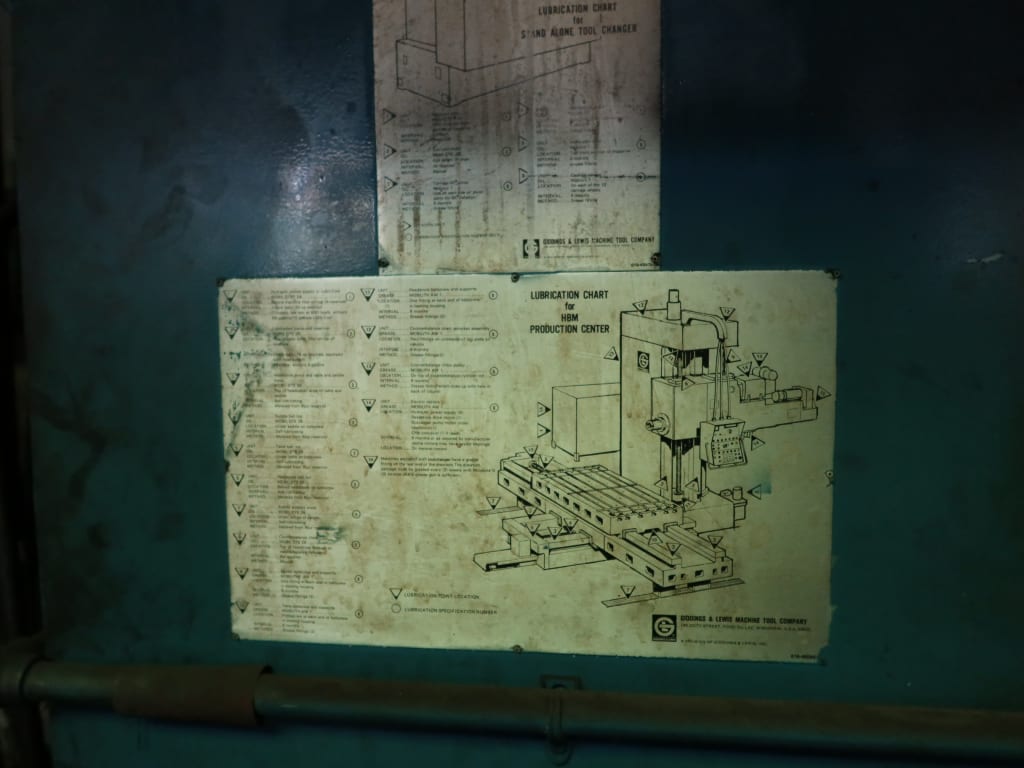

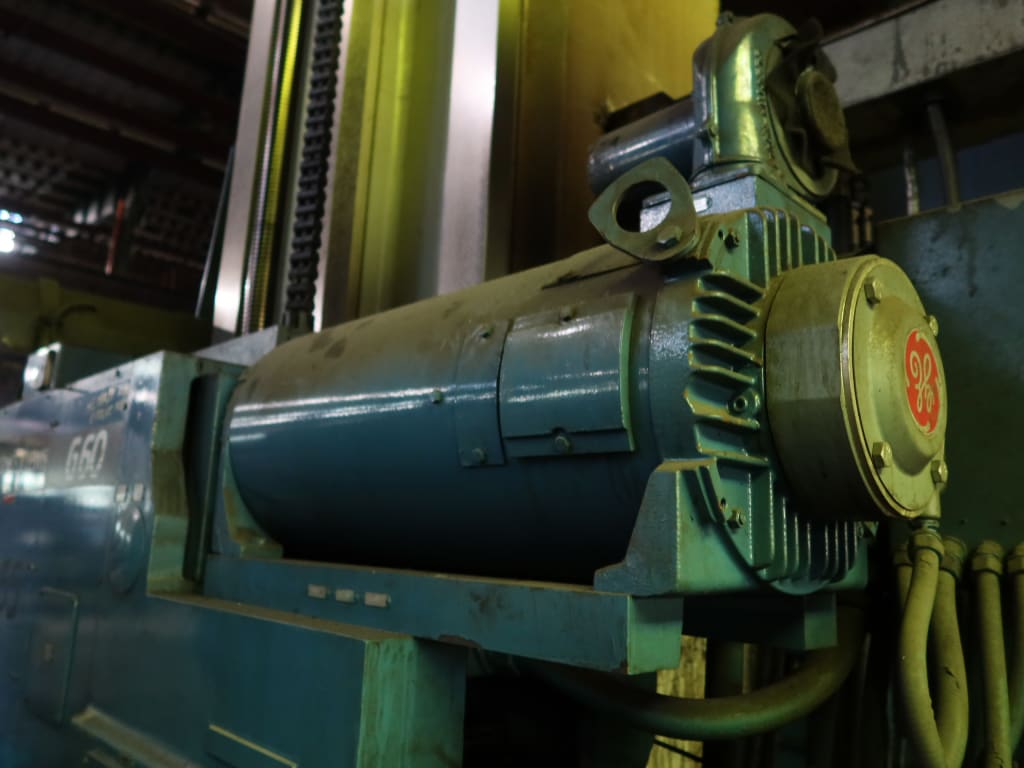

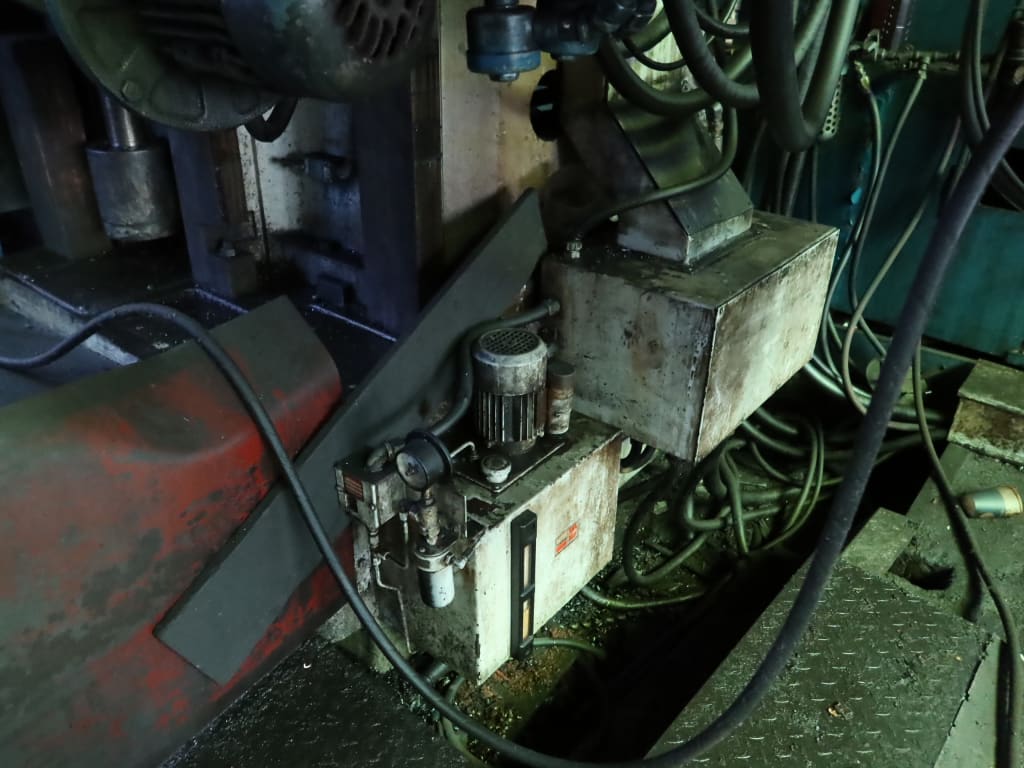

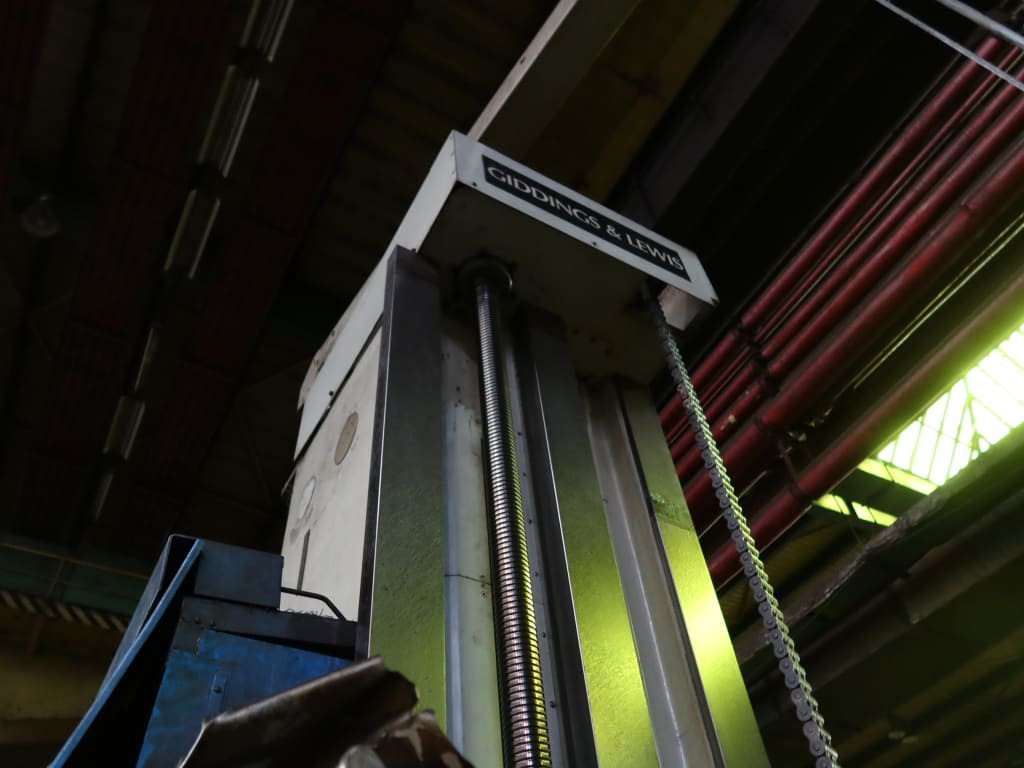

Giddings & Lewis Horizontal Boring Mill (2002)

Rotary Table: 1500 X 2400 mm, set on the cross saddle; Strokes X = 2500 mm, Y = 2500 mm,W = 1500 mm, Z = 1000 mm; Cross saddle dimensions: L = 2750 mm, l = 1500 mm

Essential Information

General Information

- Auction Dates

- Starts: 07 October 2025 at 07:00 BSTEnds: 12 November 2025 at 13:00 GMT

- Site Address

- Bulevardul Basarabia 250Bucuresti 030352Romania

- Viewing Days

- 10 November 2025 at 07:00 GMT - 11 November 2025 at 14:00 GMTViewings strictly by appointment only – Please contact Apex to make an appointment.

Fees & Payment

- Currency

- EUR

- Buyers Premium

- 18% or as specified on individual items

- Payment

General payment information

- A link to the invoice will be emailed to successful bidders

- Payment is due immediately on receipt of invoice

- All payments must be made in the currency on the invoice issued.

- Accepted forms of payment are bank transfer ONLY. We do NOT accept payment by card, cash or cheque

- NB: Please reference invoice number on bank transfer.

Goods

- Clearance days

- 24 November 2025 at 07:00 GMT - 19 December 2025 at 14:00 GMTCollections strictly by appointment only. Please note lot 8 is dismantled and stored in 8 stacks as seen in pictures.

- General Collection Information

Collection

- Buyers are fully responsible for removal of items plus all transport and rigging charges.

- Items are only available for collection once the transfered funds have cleared, and a collection appointment has been booked.

- Buyers or third party movers must present an invoice to the on-site personnel when removing their items.

- Buyers must complete the removal of items within the clearance deadline. Normal removal hours are Monday to Friday, from 9am to 4pm (local time) unless otherwise stated.

- Contact and removal information will be emailed at the time invoices are issued.

- For a list of companies that can assist with removals and transportation please visit the Apex Auctions website's Service Providers section.

- Sales Contacts

- Auction informationMatei Radu AlexandruSplaiul Unirii 12, Cam 206

Muntenia Business Center

Bucuresti, sector 4

040035

Romania rmatei@apex-group.com+40735521661